Building a Locost does seem to be a lot of “hurry up and wait”. So many aspects of the build are interconnected, that if one part holds you up, you can’t do much else. Our next big thing to do is put in the floor. We want to do this next because it’s easier to do with the chassis up side down. However, before putting the floor in you need:

a) the panelling to do it.

b) to drill the holes for the transmission tunnel panels.

We can’t do (b) because:

a, again) we don’t have the panelling.

c) it’s better to put in the brake lines while the panels are out.

So we need to order the brake lines. This requires estimating their length, and selecting the correct fittings for the end. You need to know which fittings beforehand, because the shop will flare the ends for us, but the nuts have to be in place before flaring. To know which nuts you need requires knowing which nuts the brake calipers use. So we need to find brake calipers. Nobody on this planet sells brake calipers. Somewhere in the rant above is (d), (e) and (f).

To be fair, it’s not true that nobody sells calipers. We had a lot of help on the forum to know where to look, and phonecalls to some very helpful people (Midas, Rand Ford and A.T.E.) put us on the right path. Calipers will be got next week, hooray.

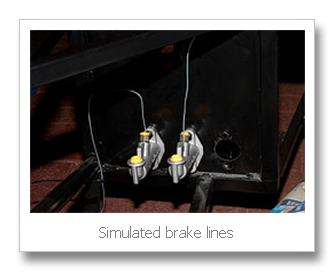

To figure out how long our brake lines need to be, we laid “simulated” brake lines using normal fencing wire. This was bent and shaped to the chassis, and held in place with cable ties. We added a few loops here and there which can be lengthened or tightened to provide a reasonable margin for error. We also were cognisant of where the T-pieces were, and made suitable breaks in the wire at these points. Once we were happy with the layout of the wiring, it was removed, straightened and measured.

Our aluminium panels have been bought and paid for, and we hope to fetch them on Tuesday – what a laugh that was. It’s amazing how certain suppliers act like they are doing you a favour. This is an actual quote from the chap at the alu place:

D (3 days after the first email): “As requested in my previous email, please confirm order, price and date of delivery.”

Supplier: “I WILL REPLY ASAP, THANKS SIR”

Perhaps his caps-lock got stuck, or perhaps he just needs a holiday?

Nonetheless, it’s now cut and ready, so when we get it we’ll have a number of tasks ahead of us.

Despite all this procurement hassle, it’s not been complete idleness. The Lobro joints are in the process of being grease-packed. That was a pleasant buying experience, with the supplier flying two tubs of the fancy CV grease (Everon) up to Jhb for us. Very cool – I recommend them.

We’ve also been back to the scrappy (as is apparent from all the pics), for almost the last donor bits. We got our steering column (including switch array and ignition), handbrake and seat runner (hopefully a plan can be made to fit it).

I aim to update the various “summary” pages with what has been learnt so far (diff, steering column, front uprights, brakes) at some point in the near future. I’ve also been playing a bit with blog software options – hence the new picture design. However, I’ll probably be back to the old style in the next post.

B